Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the realm of everyday materials, roll paper stands out as a versatile and essential component found in various applications. From kitchen rolls to industrial tissues, roll paper has woven itself into the fabric of our daily lives. According to Dr. Emily Carter, a leading expert in the paper manufacturing industry, "Roll paper is not just a product; it represents a part of our culture, facilitating convenience and cleanliness in countless settings." This statement underscores the importance of roll paper, emphasizing its role in enhancing efficiency and comfort in various environments.

The utility of roll paper extends beyond mere functionality; it embodies a blend of practicality and innovation. In households, it serves as a reliable tool for cleaning and food preparation, while in commercial spaces, it is indispensable for hygiene and operational efficiency. Whether it’s the familiar sound of tearing sheets in the kitchen or the sight of dispensers in restrooms, roll paper has cemented its place in daily routines. Through exploring the diverse types and uses of roll paper, we gain insight into how this seemingly simple product significantly impacts our lifestyles and industries alike.

Roll paper is a versatile material commonly used in various applications, from printing to packaging. Typically produced in a continuous length, roll paper is characterized by its flexibility and adaptability, consisting of several components such as cellulose fibers, fillers, and additives that enhance its performance. The primary material, cellulose, is derived from wood pulp, which is processed to create smooth, high-quality paper suitable for numerous uses. According to the Paper and Paperboard Packaging Environmental Council, the production of roll paper has increased significantly in recent years, contributing to the packaging sector, which is expected to experience growth at a compound annual growth rate (CAGR) of 3.7% through 2026.

The composition of roll paper can vary based on its intended use. For instance, thermal roll paper, commonly utilized in receipt printers, includes a coating that reacts to heat, allowing for image reproduction without ink. In contrast, kraft paper, known for its strength and durability, is often used in packaging applications. Industry reports reveal that demand for eco-friendly roll paper options is on the rise, driven by consumer preferences for sustainable products. The trends indicate that by 2025, around 60% of roll paper products will be produced using recycled materials, reflecting a growing commitment to reduce environmental impact while meeting the needs of consumers in everyday life.

Roll paper is a versatile product widely used in various sectors due to its convenient form and functionality. Common types of roll paper include thermal paper, kraft paper, and tissue paper, each serving unique purposes in everyday applications.

Thermal paper is extensively utilized in receipt printing and labels, valued for its quick-drying properties and high-quality printing results. According to a report from Smithers Pira, the global thermal paper market was valued at approximately $4.8 billion in 2020 and is expected to grow significantly, indicating its importance in retail and logistics.

Kraft paper, on the other hand, is renowned for its strength and durability, making it ideal for packaging and wrapping. It's commonly used in shopping bags, boxes, and even for stationery products. The versatility of kraft paper extends to the food industry, where it serves as a safe and biodegradable option for food packaging. The demand for sustainable packaging alternatives has surged, with forecasts suggesting that the global kraft paper market will reach nearly $100 billion by 2026, as more businesses transition to eco-friendly options.

Tips: When selecting roll paper for specific applications, consider the weight and thickness required for your project. For example, using heavier weight paper for packaging will ensure better durability during transport. Additionally, check for certifications that indicate sustainability, such as FSC (Forest Stewardship Council) approval, to contribute positively to environmental efforts.

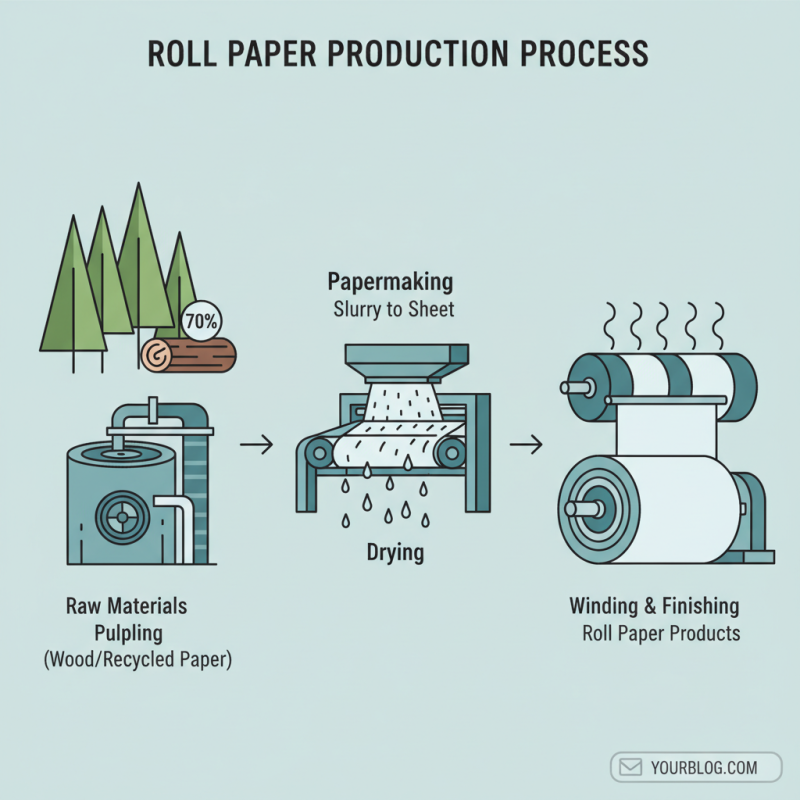

Roll paper is an essential product in various industries, and its production involves a meticulous process that ensures high quality and efficiency. The production of roll paper typically begins with the sourcing of raw materials, primarily cellulose fibers from wood or recycled paper. According to a report by the Paper and Forest Products Industry, approximately 70% of the world's paper is produced from wood-based fibers, highlighting the industry's reliance on sustainable forestry practices. Once the raw materials are harvested, they are processed into pulp through methods such as mechanical or chemical pulping, which breaks down the fiber structure to create a slurry for papermaking.

After pulp preparation, the next critical step is the formation of the paper itself. The slurry is fed onto a continuously moving mesh screen, where water is drained, and the fibers are compacted to form a wet sheet. This sheet undergoes pressing and drying stages, typically using heated rollers, which reduces moisture content and enhances the strength and uniformity of the paper. As per recent industry analysis, the global demand for roll paper is expected to grow by 3.5% annually, driven by sectors such as packaging and hygiene products, further emphasizing the importance of efficient production methods. The entire process not only reflects advancements in technology but also addresses the increasing need for sustainable practices within the paper industry, aiming to minimize environmental impact while meeting consumer demand.

Roll paper, a versatile product used across various sectors, plays a crucial role in our daily lives. In the retail and grocery industries, roll paper is primarily utilized for point-of-sale (POS) receipts, ensuring smooth transaction processes. According to a report by Smithers Pira, the global demand for thermal paper used in receipts is projected to reach 2.9 million tons by 2024. This signifies not only its widespread adoption but also the growing reliance on such paper for efficient consumer interactions.

In the healthcare sector, roll paper serves essential functions beyond mere documentation. It is commonly employed for printing labels, patient charts, and other critical materials. A study from the Healthcare Packaging Association highlights that the demand for medical roll paper has increased by approximately 12% annually, driven by the need for hygiene and traceability in patient care. Moreover, the food industry utilizes roll paper for packaging, labels, and wrappers, contributing significantly to the packaging market, which is estimated to surpass $400 billion by 2025, indicating the vital place of roll paper in ensuring food safety and compliance.

The education sector has also embraced roll paper, particularly for printers and copiers, facilitating the preparation of educational materials. As schools transition to more digital formats, the need for roll paper remains stable, especially for producing larger-format documents and posters. Analysts expect this trend to persist, reflecting the ongoing importance of roll paper in supporting various logistical and operational functions across diverse industries.

Roll paper, commonly used in various applications such as thermal printing, packaging, and more, poses environmental concerns due to its production and disposal processes. The manufacturing of roll paper often involves the use of significant natural resources, leading to deforestation and water pollution. Furthermore, the disposal of roll paper can contribute to landfill waste, particularly if it is not recycled properly. To mitigate these impacts, it is vital for consumers and businesses to adopt more sustainable practices surrounding roll paper use.

One effective way to reduce the environmental footprint of roll paper is through recycling. Proper recycling channels can help ensure that roll paper is repurposed instead of ending up in landfills. Many facilities accept roll paper, especially if it is free from contaminants such as plastic or food residues. By prioritizing recycling, individuals can contribute to a circular economy, which reduces the demand for fresh raw materials and minimizes waste.

**Tips:** Always check local recycling guidelines to determine the best methods for disposing of roll paper. Consider switching to products made from recycled materials, and explore digital alternatives to reduce reliance on paper altogether. Engaging in these practices not only helps the environment but also encourages organizations to adopt more sustainable production methods.

| Dimension | Description | Usage | Environmental Impact | Recycling Information |

|---|---|---|---|---|

| Type of Roll Paper | Standard paper rolls, thermal rolls | Used in printers, cash registers, and packaging | Deforestation and energy consumption | Can be recycled and reused |

| Common Sizes | Width ranges: 2 inches to 18 inches | Packaging, arts and crafts | Environmental pollution if not disposed properly | Check local recycling guidelines |

| Materials | Wood pulp, recycled paper | Office supplies, social events | Carbon footprint associated with production | Identify paper types for effective recycling |

| Alternatives | Digital receipts, bamboo paper | Reducing waste in stores | Lower environmental impact options | Explore sustainable alternatives |