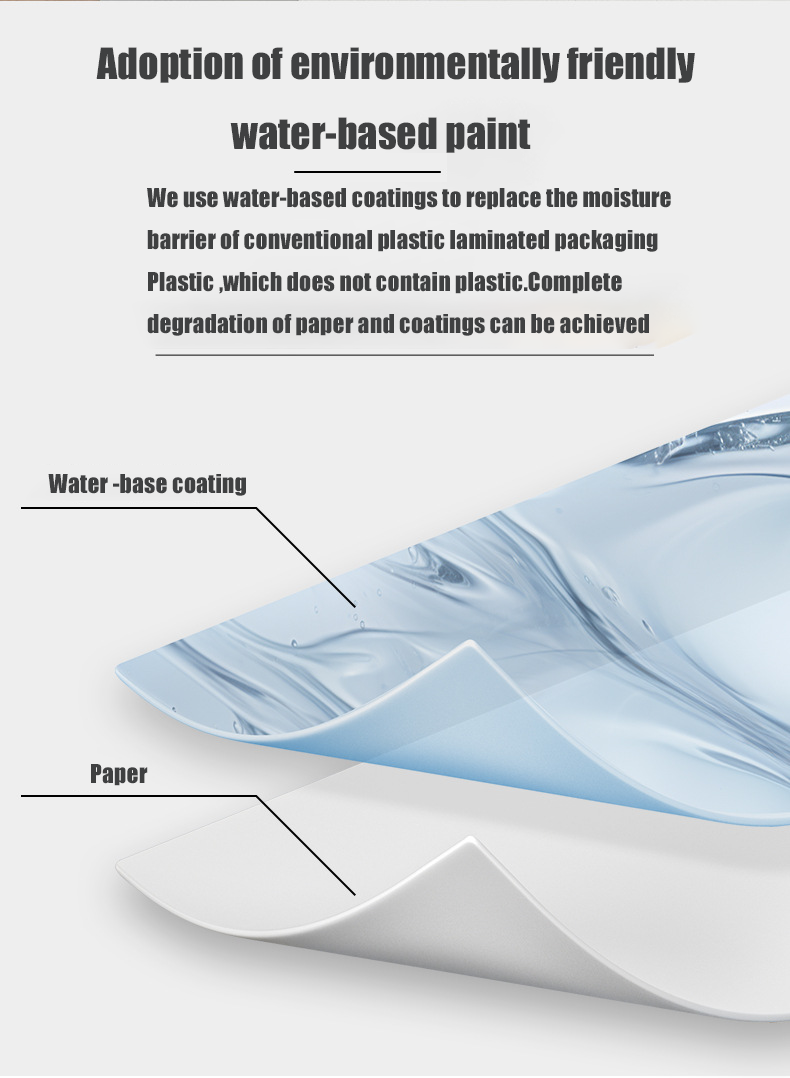

Custom Water Base Coated Paper For Paper Cup

We use water-based coatings to replace the moisture-proof function of conventional plastic film packaging. No plastic allows complete degradation of paper and coating

Product Specification

| Parameter | Details |

| Weight | 150g, 180g, 210g, 230g, 250g,320g etc. |

| Coating Type | Eco-friendly water-based coating |

| Water Resistance | ≥ 72 hours |

| Oil Resistance | Level 4 or above (based on KIT test) |

| Color | White, brown |

| Applications | Food paper cups, takeaway boxes, lunch boxes, paper bags |

01

0102030405

(1) We have 17 sets machine, two PE coated machines, one is 200 meters per minute, the other is 300, the monthly production capacity is 2800 tons, single and double lamination can be done.

(2) One flexo printing machine, BEST flexo printing machine in South China, offer 7 colors printing with high speed of 300m/minute. Complete size, suitable for variety of cup fan size. We can make design as you provide our pictures.

(3) Three automatic high speed die-cuttining machines,it is flexible for different sizes of paper cup fan, and cutting deviation is ±1mm, make sure the paper cup fan size is exactly same and friendly to your paper cup machine.

(4) Three punching machines,this machine can take off the fan from the printed jumbo roll automatically, saving much labor and time.

(5) One high speed slitting machine, It is usually used for producing bottom roll,can do 40-140mm.

(6) One high-speed paper sheet cutting machine,it is usually used for producing paper sheet, we can accept 560*560 to 960*960mm, also can do 560*960mm paper sheet.