0102030405

Differences Between PE Coated Paper and Release Paper

2025-09-25

Differences and Uses of PE Coated Paper and Release PaperPE coated paper and release paper share many similarities, such as their waterproof and oil-proof properties. However, they differ significantly in structure, manufacturing, and application.

Differences Between PE Coated Paper and Release Paper

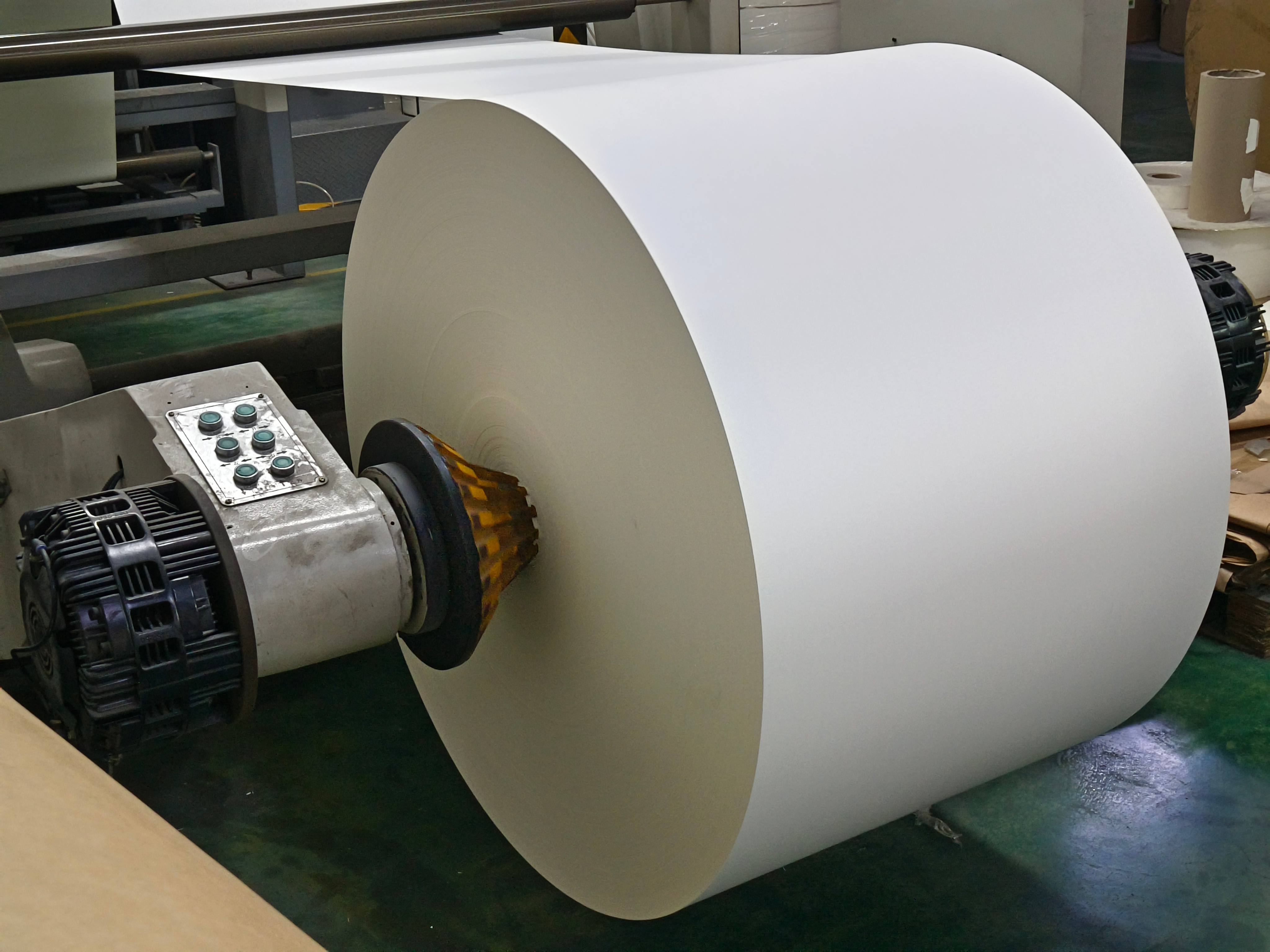

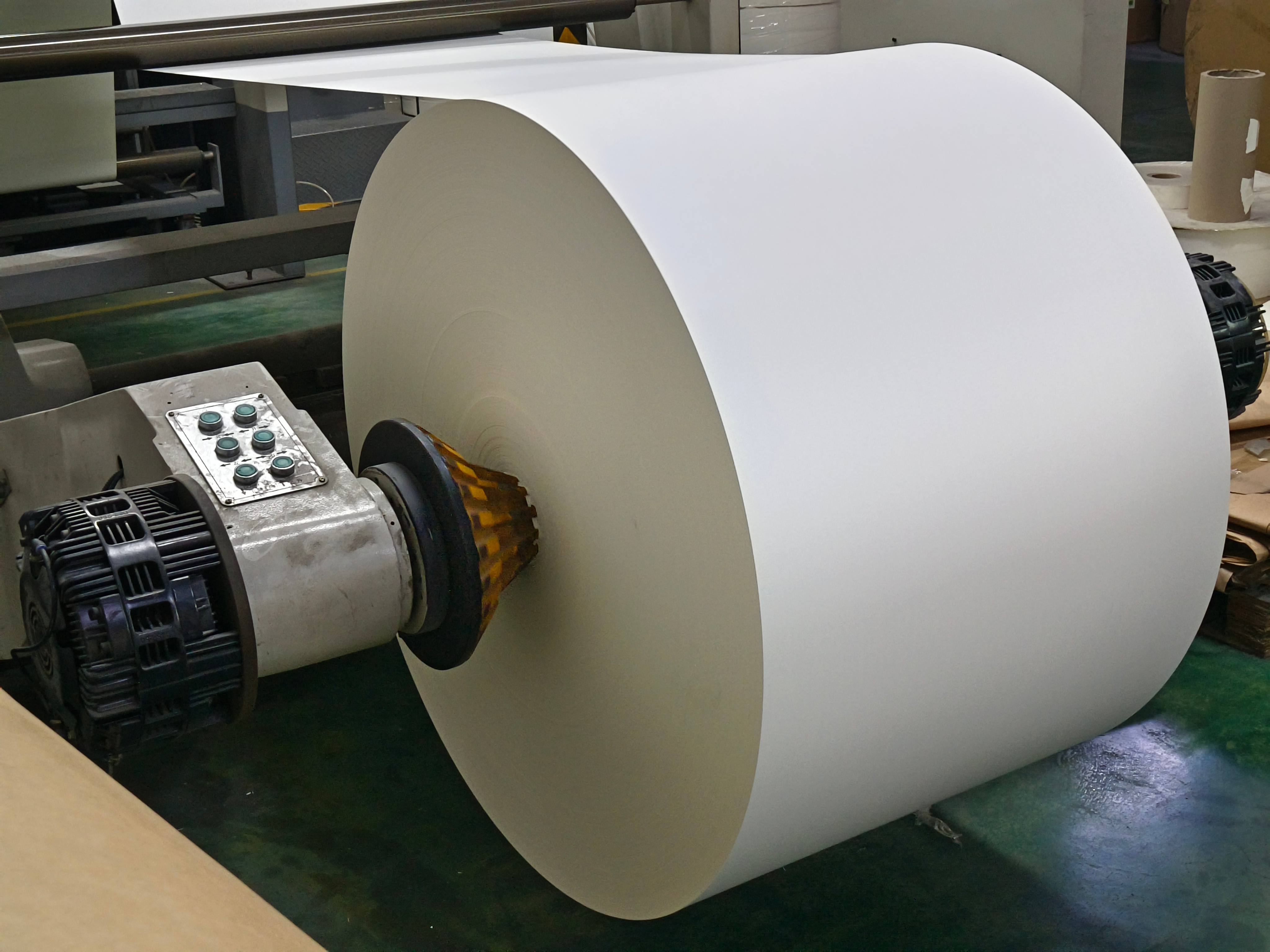

PE Coated Paper:

- PE coated Paper Consists of two layers: the base paper and a polyethylene (PE) coating.

- During production, PE plastic particles are melted at high temperatures using a casting coating machine and evenly applied to the surface of ordinary paper via rollers. This process results in a PE-coated paper roll.

- The PE layer enhances the paper’s tensile strength and burst resistance while providing excellent waterproof and oil-proof protection.

- It is known for its flexibility and durability, making it ideal for packaging applications.

Release Paper:

- Release paper typically has three layers: backing paper, a coating layer, and silicone oil.

- After applying the coating, a layer of silicone oil is added, giving the paper its non-stick properties.

- Release paper is also referred to as silicone release paper due to its ability to resist adhesion and withstand high temperatures, moisture, and oils.

Applications of PE Coated Paper and Release Paper

Uses of PE Coated Paper:

- Chemical Industry: Used for packaging desiccants, camphor balls, detergents, preservatives, etc.

- Food Packaging: Ideal for items like paper cups, bread bags, hamburger wrappers, coffee packaging bags, and more.

- Wood Products: Commonly used for tongue depressors, ice cream scoops, toothpicks, and cotton swabs.

- Paper Industry: Applied in light-coated paper packaging, copy paper (neutral paper), etc.

- Daily Life Items: Suitable for wet tissue bags, salt packaging, and disposable paper cups.

- Pharmaceutical Packaging: Used for medical equipment packaging, drug packaging, and pesticide packaging.

- Other Uses: Applied in test machine paper, aviation bags, seed bag paper, self-adhesive base paper after silicon coating, kraft paper tape, anti-rust packaging with anti-rust oil, and disposable travel products.

Uses of Release Paper:

- Release paper prevents pre-preg materials from getting contaminated or sticking together.

- It is categorized into single-plastic release paper, double-plastic release paper, and plastic-free release paper.

- Its primary functions include anti-isolation and anti-adhesion, making it essential in industries like electronics, automotive foam, printing, food packaging, and healthcare.

- It is commonly used alongside adhesive materials, especially in the adhesive tape and self-adhesive industries.

Conclusion

While both PE coated paper and release paper offer waterproof and oil-proof characteristics, their structures and uses are quite different. PE coated paper is best suited for durable and moisture-resistant packaging, whereas release paper plays a critical role in preventing premature adhesion in manufacturing and industrial applications.