How Are Colorful Patterns Printed on Paper Cups? A Step-by-Step Guide to Flexographic Printing Technology

In our everyday lives, we encounter a wide variety of Disposable Paper Cups, many of which feature vibrant and eye-catching designs. These patterns not only enhance the drinking experience but also serve as an excellent marketing tool for businesses. But have you ever wondered how these intricate patterns are printed onto paper cups?

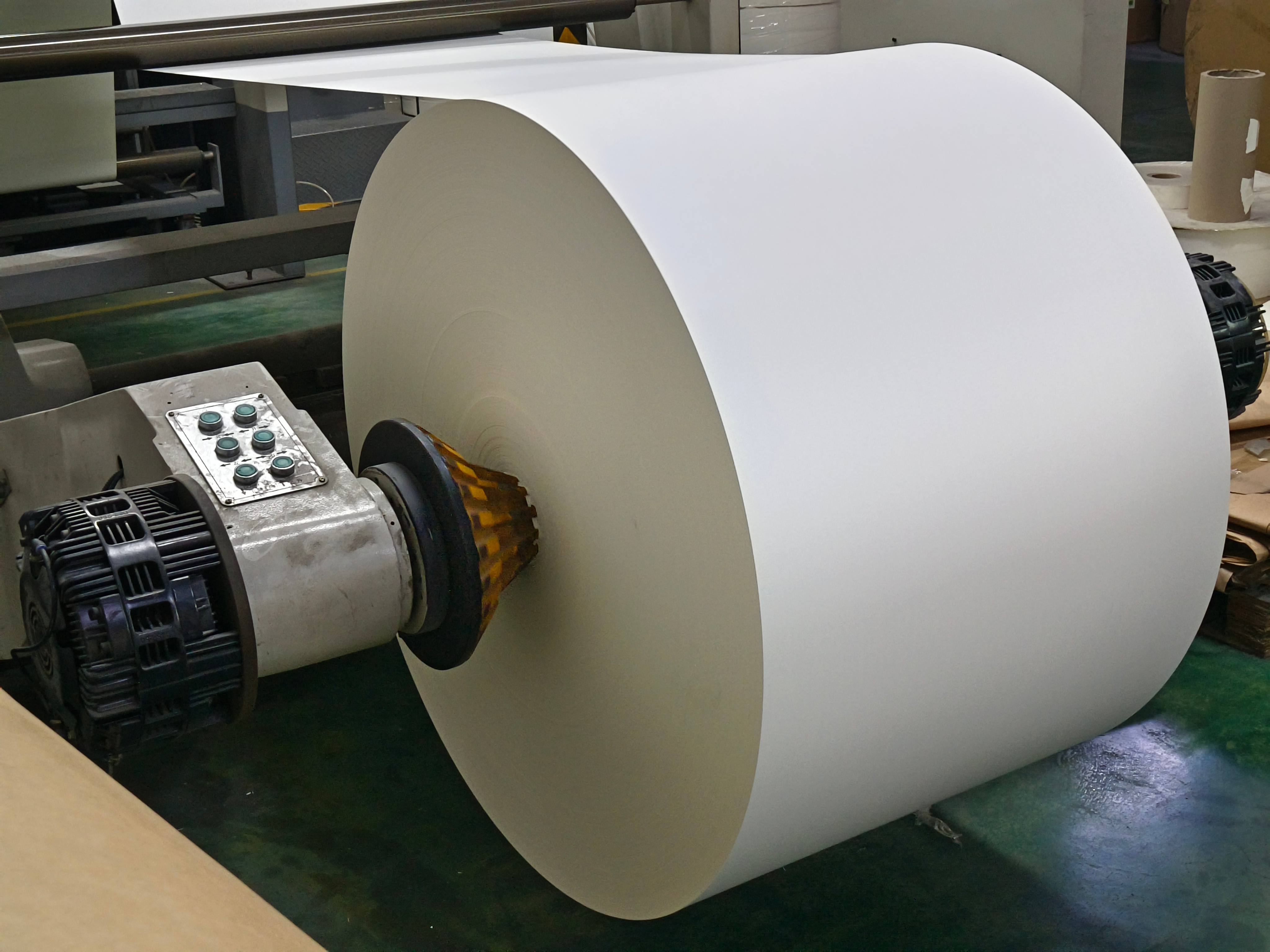

Raw Materials For Paper Cups

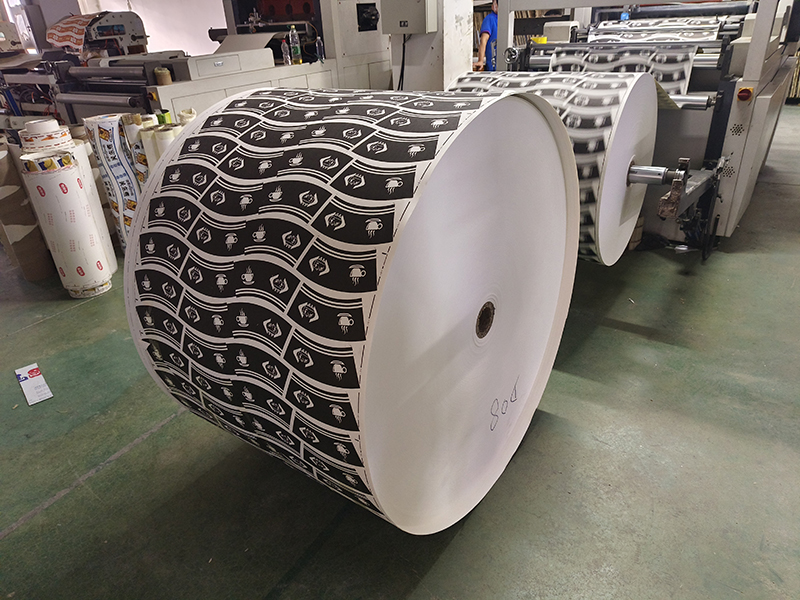

The primary materials used in paper cup production include food-grade wood pulp base paper combined with a food-grade PE (polyethylene) film. This combination is known as food-grade PE-coated paper. The pattern is printed directly onto the PE-coated paper roll before being die-cut into semi-finished paper cup fans. These fans are then processed into finished paper cups using specialized machinery.

● The side coated with PE film becomes the inner wall of the paper cup, providing waterproof, oil-resistant, and heat-resistant properties.

● The uncoated side serves as the outer wall of the paper cup, where the patterns are printed.

Paper Cup Production Process

The printing process for paper cup fans typically involves flexographic printing, a widely-used technique in the food packaging industry.

What Is Flexographic Printing?

Flexographic printing is a type of letterpress that has become the go-to method for printing on paper cups. It utilizes eco-friendly inks such as water-based, UV, or solvent-based inks, making it an ideal choice for environmentally conscious manufacturers.

How Does Flexographic Printing Work?

The key component of flexographic printing is the printing plate, which is usually made from flexible resin or rubber. Here’s how the process works:

1. Ink Transfer: Ink is transferred from the ink fountain roller to the anilox roller, which ensures a precise and consistent ink layer.

2. Printing Plate Inking: The inked anilox roller applies ink to the raised areas of the printing plate, corresponding to the design or pattern.

3. Printing Pressure Application: The impression cylinder applies pressure, transferring the ink from the printing plate onto the PE-coated paper roll.

4. Drying Process: The printed material is dried using infrared hot air or UV curing techniques to ensure the ink adheres properly and dries quickly.

This advanced printing technology allows for high-quality, durable, and visually appealing designs on paper cups, meeting the demands of both consumers and businesses alike.By understanding the flexographic printing process, you can appreciate the craftsmanship behind the colorful patterns on your favorite paper cups. Whether for branding or aesthetic purposes, this technology plays a crucial role in enhancing the appeal of disposable paper products.