How is a PE Coated Paper Roll Transformed into a Paper Cup?

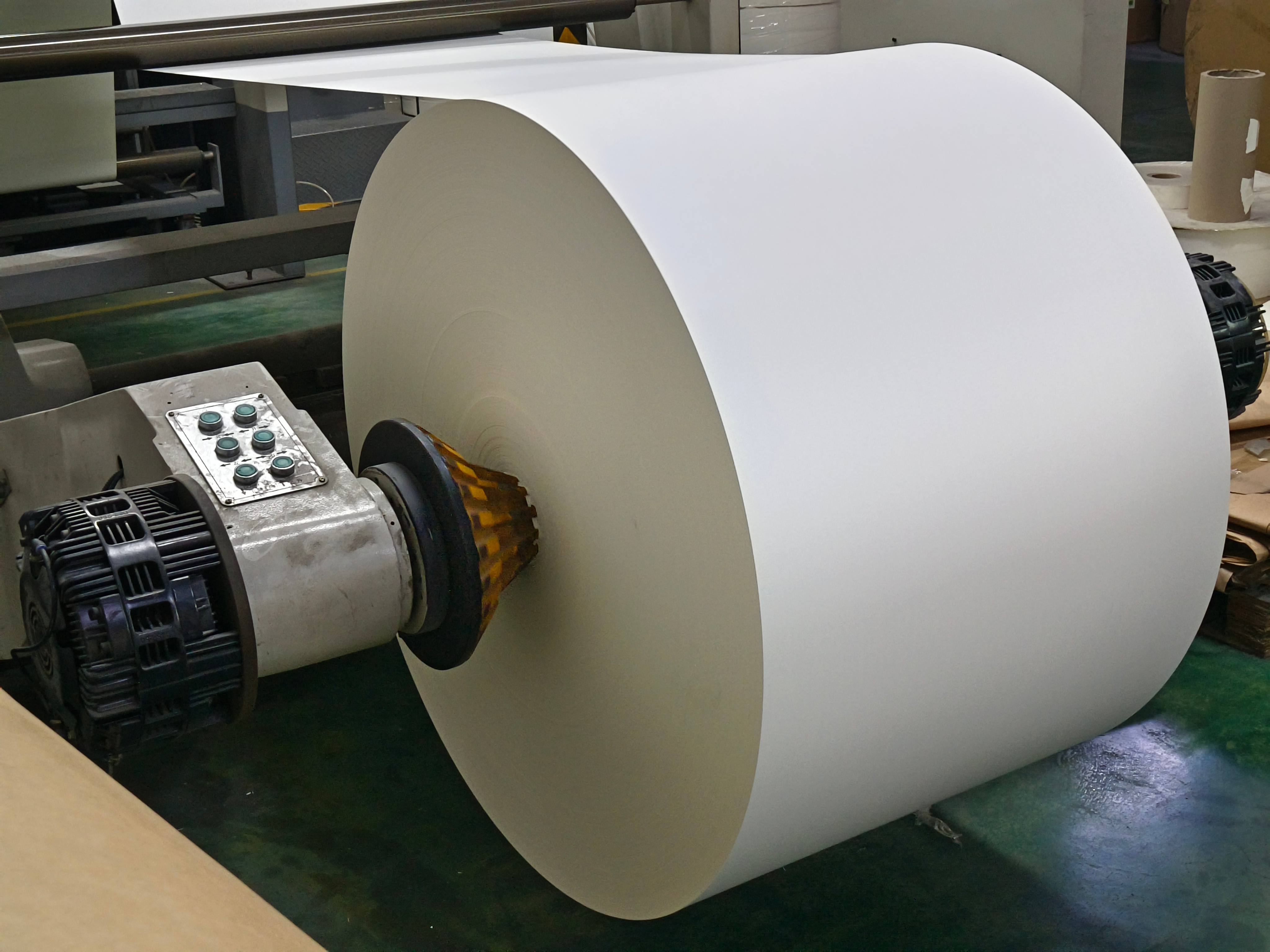

A Step-by-Step GuidePe Coated paper roll is widely utilized in paper cup manufacturing due to its waterproof properties, which ensure liquid resistance and leakage prevention. Below is an optimized explanation of the production process, designed for clarity and SEO-friendliness:

1. Printing: Customizing with Flexographic Technology

The process begins with flexographic printing, a high-speed method ideal for large-scale production. Flexible rubber plates, engraved with the desired design, are mounted on a printing press. Water-based, food-safe ink is applied to the paper roll, transferring vibrant graphics, logos, or text onto the surface. This eco-conscious printing technique ensures precision while meeting food-contact safety standards.Printed PE Coated Paper Roll

2. Cutting: Precision into "Paper Cup Fans"

The printed roll is fed into a rotary cutting machine, which slices it into flat, pre-shaped sheets called "paper cup fans." The dimensions of these sheets are tailored to the required cup size (e.g., 6 oz, 12 oz), ensuring consistency in production.Paper Cup Fan Sheets

3. Forming: Shaping the Cup Structure

The cup fans are conveyed into a cup-forming machine, where curved rollers mold the paper into a cylindrical shape. The bottom of the cup is formed by folding the paper into a disc and sealing it with a thin layer of polyethylene film. This layer acts as a barrier against liquid penetration, critical for maintaining waterproof integrity.Paper Cup Bottom Formation

4. Sealing and Trimming: Ensuring Leak Resistance

The sealed cup bottom undergoes precise trimming to match the desired size. The cup’s top edge is then rolled outward to create a smooth, drink-friendly rim. This step guarantees a secure structure while enhancing comfort.

5. Curling: Finishing the Cup Rim

The cup’s upper edge is curled outward using specialized machinery. This final shaping prevents spills and provides a ergonomic grip, optimizing both functionality and usability.

6. Quality Control: Rigorous Inspection

Completed cups are systematically inspected for defects, such as misalignment, weak seals, or print inaccuracies. Automated systems and human oversight ensure compliance with size, shape, and sealing strength specifications. Defective cups are immediately discarded to maintain high-quality output.

7. Packaging: Ready for Distribution

Qualified paper cups are neatly stacked and placed in sturdy corrugated cardboard boxes to prevent damage during transportation. At this stage, the products are ensured to be safely delivered to the customers, and the labels clearly indicate the product specifications and batch information.

Comprehensive Solutions for Paper Cup Production

Our product portfolio encompasses all the core materials required for paper cup manufacturing, including:

PE-coated paper rolls

Cup bottom paper rolls

Cup fan paper sheets

PE-coated kraft paper rolls

We also offer customized services, where we can design and produce disposable paper cups based on the brand requirements of our clients. With globally advanced production equipment and a strict quality management system, we are committed to delivering solutions that are environmentally friendly, durable, and cost-effective.

Why Choose Our Services?

Advanced Technology: State-of-the-art machinery ensures precision and scalability.

Material Expertise: Specialized materials for durability and food safety.

Customization: Full branding support and tailored cup designs.

Global Standards: Compliance with international quality and safety regulations.

Get Started Today

Ready to transform your ideas into premium paper cups? Contact us for a free consultation, detailed specifications, or a competitive price list. Let’s collaborate to create sustainable and customer-pleasing products!