PE Coated Paper vs PLA Coated Paper: Which Is Right for Your Business

In today's rapidly changing world, sustainability has become a global priority that influences various industries, including packaging and disposables. As businesses strive to meet the increasing demand for environmentally friendly products, selecting the appropriate Coated Paper for items such as paper cups is more critical than ever. This article delves into a detailed comparison of the two most prevalent types of coated papers—PE (Polyethylene) and PLA (Polylactic Acid)—to assist you in making an informed decision tailored specifically for your business.

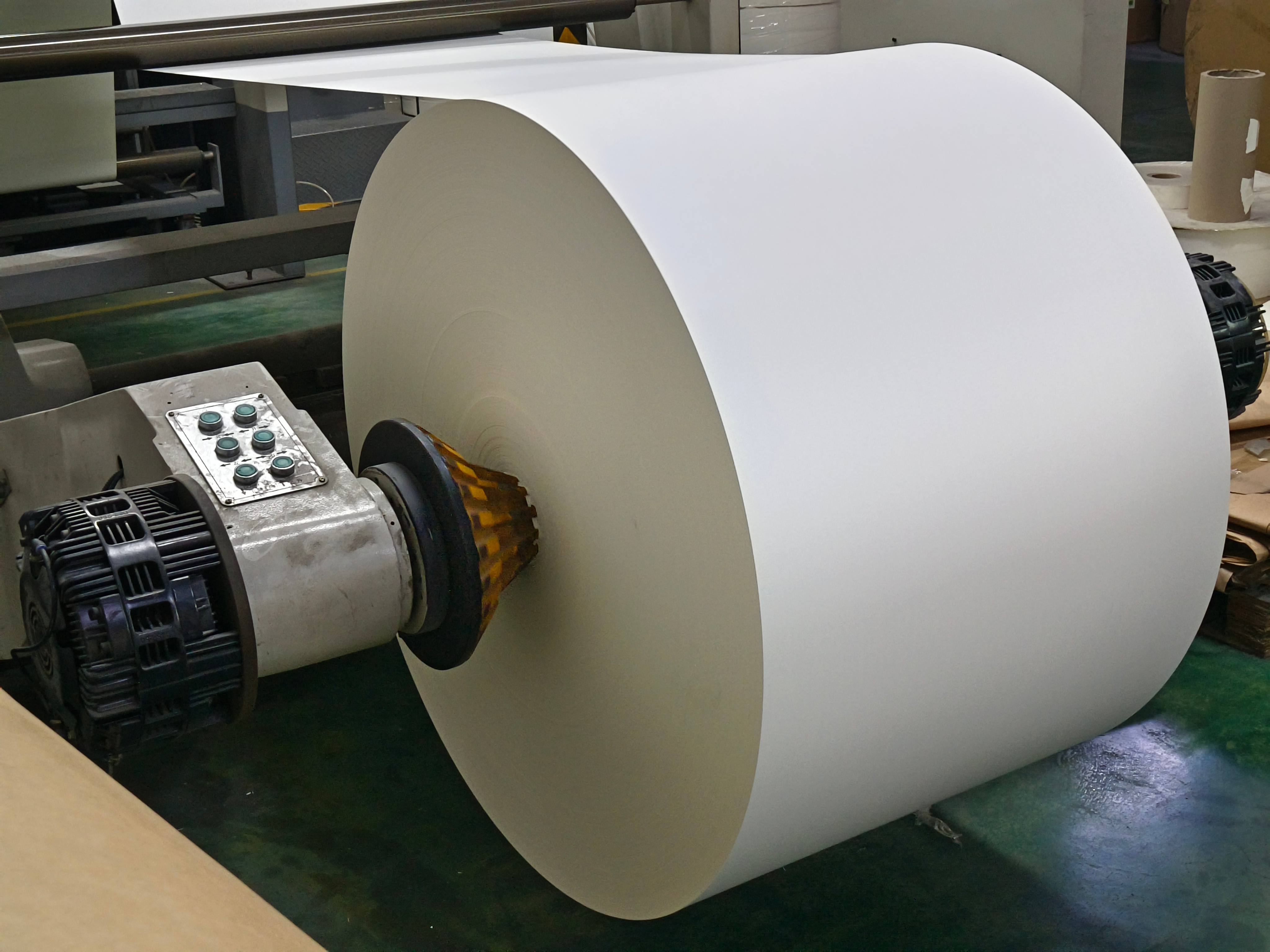

- What Is Pe Coated Paper?

PE coated paper represents the industry standard when it comes to disposable cups. It features a polyethylene coating that provides robust moisture resistance, making it suitable for both hot and cold beverages. Its widespread acceptance stems from its ability to withstand varying temperatures without compromising structural integrity.

Pros:

- Cost-effective solution for mass production

- Widely accepted across different markets

- Perfect for high-speed production lines, ensuring efficiency and speed

Cons:

- Not biodegradable, contributing to environmental waste issues

- Limited recyclability, posing challenges for sustainable practices

- What Is PLA Coated Paper?

PLA coated paper utilizes polylactic acid, a biodegradable material derived from renewable plant starches such as corn or sugarcane. Brands aiming to enhance their green image often prefer this option due to its eco-friendly nature.

Pros:

- Fully compostable under specific conditions, reducing environmental impact

- Eco-friendly and plant-based origin, aligning with sustainable values

- Ideal for businesses focused on building a strong, sustainable brand identity

Cons:

- Higher cost compared to traditional alternatives

- Requires controlled industrial composting conditions to break down effectively

- Which One Should You Choose?

The decision between PE and PLA coated paper ultimately depends on your business priorities and market demands. If your primary focus lies in achieving cost-effectiveness and operational efficiency, then PE coated paper serves as the optimal choice. On the other hand, if your target market highly values eco-friendliness and you're dedicated to constructing a green brand, opting for PLA coated paper would be the better path forward.

NANNING LVKE PAPER SPECIALIZE IN SUPPLYING DISPOSABLE PAPER CUP FAN, PAPER CUP RAW MATERIAL, PE COATED KRAFT PAPER, PE FREE COATED PAPER, CKB PAPER, GC1/C1S/FBB/IVORY BOARD, AND OTHER TYPES OF PACKAGING PAPERBOARD.

There is no universal answer that fits all scenarios. The ideal coating type varies based on individual business needs, market trends, core values, and budget constraints. If you remain uncertain about which option best suits your enterprise, our team of experts stands ready to provide guidance and help you identify the perfect solution tailored to your unique requirements. By considering these factors carefully, you can make a well-informed choice that aligns with both your business objectives and the growing emphasis on sustainability.

NANNING LVKE PAPER CO.,LTD

CONTACT:VICKY LI

EMAIL:VICTORIA.LI@NNLVKE.COM

MOBILE/WHATSAPP:+8619977109815