PE Coated Paper: Why Paper Cups Don’t Leak – Waterproof & Food-Safe Explained

Every day, over 25 billion Paper Cups are used worldwide for coffee, tea, and cold drinks – but have you ever wondered what keeps these thin paper vessels from leaking? The answer lies in a unsung hero of packaging materials:PE Coated Paper. This specialized material combines the rigidity of paper with the impermeability of plastic, creating the perfect solution for single-use drinkware. Let’s dive into the science behind its leak-proof magic and why it remains the top choice for paper cup manufacturers.

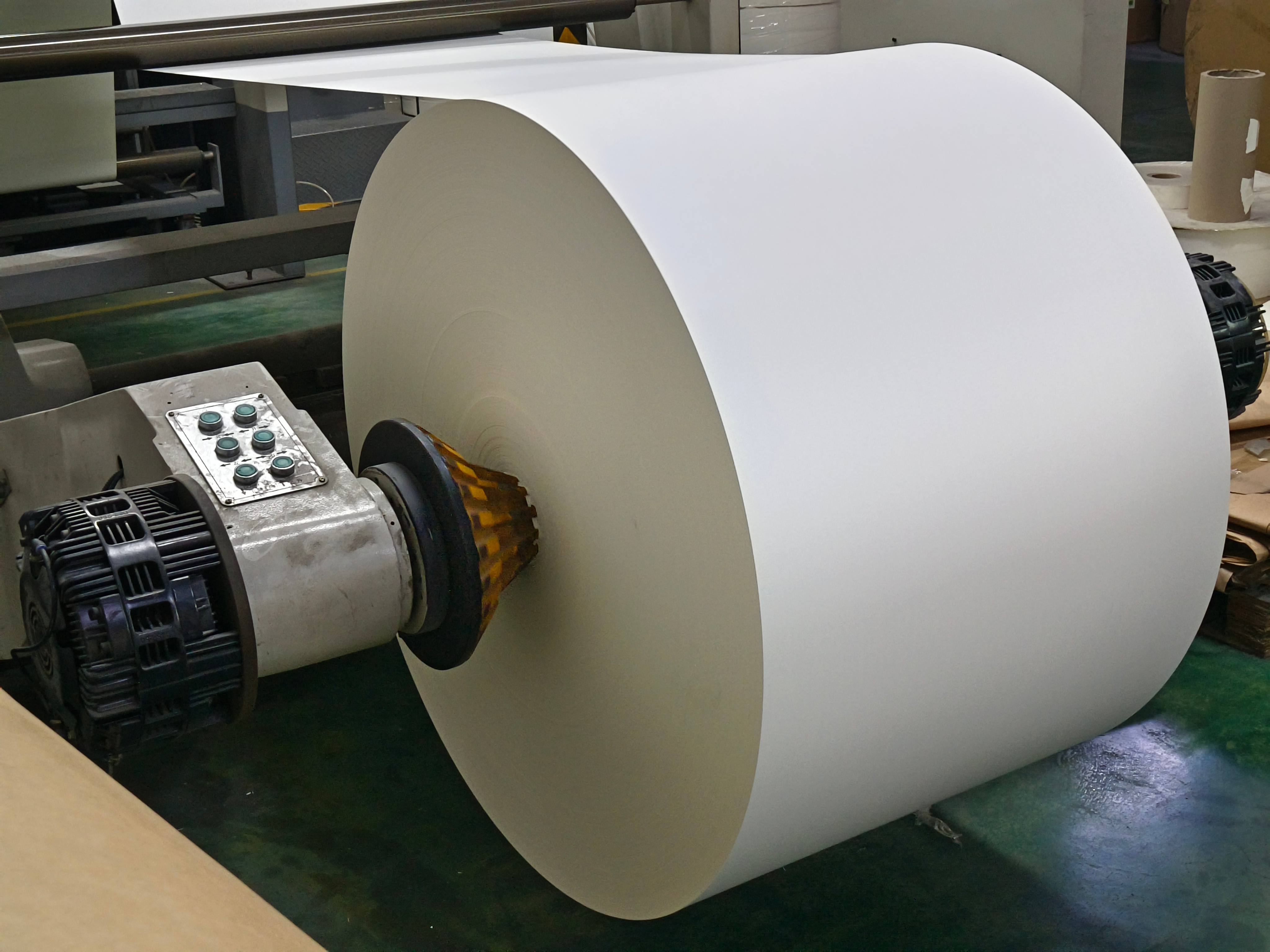

What Is PE Coated Paper?

PE coated paper (short for polyethylene coated paper) is a composite material where a thin layer of polyethylene film is bonded to base paper. The polyethylene layer acts as a barrier against liquids, while the paper provides structural support. For food contact applications like paper cups, this material must meet strict safety standards: it must comply with GB 4806.8 national food safety standards in China and FDA certification internationally, ensuring no harmful substances leach into drinks. The PE film used typically has a melting index of 7±0.5g/10min (190℃/2.16kg) to guarantee uniform coating and reliable performance.

Three Key Reasons PE Coated Paper Prevents Leaks

1. Superior Material Barrier Properties

Polyethylene is a thermoplastic polymer with inherently excellent waterproof characteristics. Its high molecular weight structure creates a dense network that blocks moisture penetration. Unlike uncoated paper, which absorbs liquid within seconds, PE coated paper resists water seepage even under prolonged contact. The film-paper bond is also critical: manufacturers use special treatments to achieve a peel strength of ≥1.2N/15mm, ensuring the PE layer doesn’t separate from the paper base even when wet.

2. Precision Coating Technology

The leak-proof performance depends heavily on the coating process, primarily using the flat extrusion upward blowing method. Here’s how it works: PE particles are dried at 80-90℃ for 4 hours to reduce moisture to ≤0.05%, then melted in an extruder at temperatures ranging from 160℃ (feed section) to 230℃ (die head). The molten PE is evenly distributed through a hanger-type die and pressed onto the base paper at 0.3-0.5MPa pressure. A dual-cooling roller system (25-35℃) rapidly solidifies the film, creating a seamless barrier. Online β-ray thickness gauges check the coating every 0.5 seconds, keeping thickness偏差 within ±3%. This precision ensures no weak spots where leaks could start.

3. Rigorous Quality Control

Even the best materials need strict quality checks. During paper cup production, edges are precisely cut with burrs ≤0.1mm to ensure tight seals at the seams. Random sampling tests include: waterproof testing (passing GB/T36392 leakage standards), heat resistance (withstanding 80℃ liquids for 10+ minutes), and heat-seal strength (≥1.5N/15mm). For food-grade cups, additional checks verify heavy metal content (total lead/cadmium/mercury ≤100mg/kg) and phthalate compliance – all critical for both safety and leak prevention.

PE Coated Paper vs. Other Cup Coatings

While PE coating dominates the market, alternatives exist. Here’s how they compare:

● PLA Coating: Made from cornstarch, PLA is biodegradable but has lower durability and heat resistance than PE. It’s less suitable for hot drinks or high-pressure applications.

● Water-Based Coating: Eco-friendly but lacks the moisture barrier performance of PE, making it prone to leaking with extended use.

● PE Coating: Offers the best balance of cost, waterproofing, and processability. It’s recyclable in specialized facilities and meets global food safety standards.

The Future of PE Coated Paper

As sustainability becomes more important, manufacturers are developing recyclable PE coated paper and exploring bio-based polyethylene options. While challenges remain in improving recycling rates, PE coating’s proven leak-proof performance and safety ensure it will remain a staple in paper cup production for years to come. Next time you sip from a paper cup, you’ll know the PE layer working silently to keep your drink where it belongs – inside the cup.