Raw Materials Required for Paper Cup Manufacturing

Disposable Paper Cups are widely used as drinking vessels in homes and public places. But have you ever wondered what materials make up these everyday items? The raw materials used in the production of paper cups play a crucial role in determining the quality, durability, and safety of the final product. Below are the primary materials involved in their manufacturing process.

1.

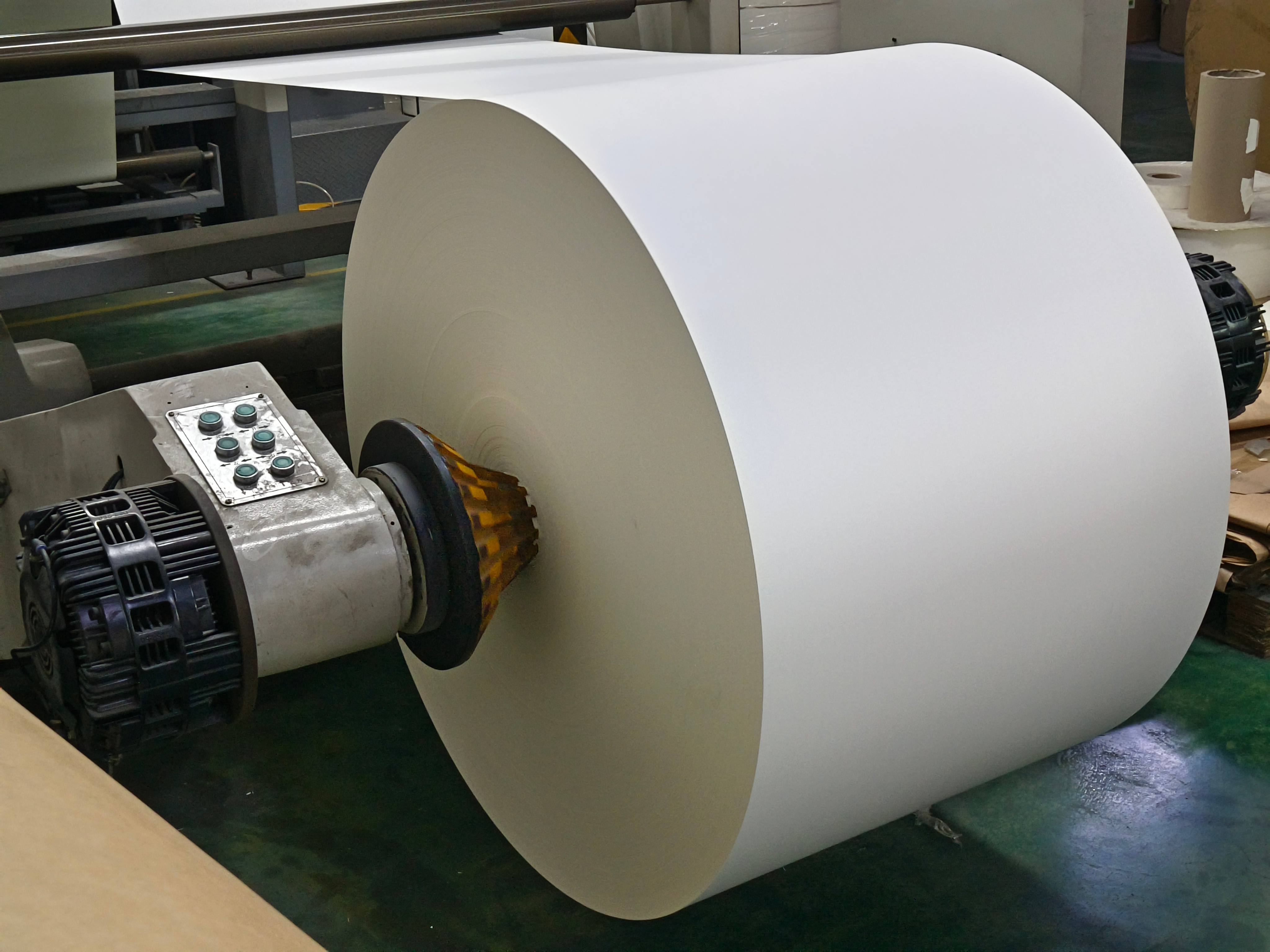

Paperboard

The foundation of any paper cup is paperboard, a thick, sturdy type of paper made from pulped wood fibers. It provides structural integrity and strength to the cup. High-quality paperboard used in food packaging is designed to be food-safe, moisture-resistant, and durable.

2.

Adhesives

To ensure the cup maintains its shape and is leak-proof, adhesives are used to bond the layers of paperboard together. These adhesives can be water-based, solvent-based, or hot-melt types, all of which must be safe for food contact.

3.

Inks

Inks are used to print logos, designs, and other graphics on the surface of the paper cup. It is essential that these inks are non-toxic and meet food safety standards to prevent any harmful substances from leaching into the contents of the cup.

4.

Coating Agents

A coating agent is applied to the inner surface of the paper cup to create a barrier that prevents liquids from soaking through the paperboard. Commonly used coatings include:

● Wax

● Polyethylene (PE)

● Silicone

Among these, polyethylene (PE) is the most widely used due to its excellent moisture resistance and durability. PE-Coated Paper cups are the standard in the current market.

5.

Additives

Sometimes, additives such as enzymes, emulsifiers, and preservatives are added to enhance the performance of the materials or extend the shelf life of the paper cups.

Conclusion: The production of disposable paper cups involves a combination of carefully selected raw materials that ensure the final product is not only functional and durable but also safe for food and beverage use. Each component—from the paperboard to the inks and coatings—plays a vital role in meeting consumer expectations and industry standards.