What are the Different Types and Applications of Cupstock Paper?

Cupstock Paper—the backbone of Paper Cup manufacturing—is engineered to provide durability, leak resistance, and aesthetic appeal, meeting diverse needs in the food and beverage industry. As demand for eco-conscious and cost-effective packaging grows, understanding the types of cupstock paper and their ideal use cases is critical for businesses aiming to balance quality, sustainability, and functionality.

1. Pe Coated Cupstock Paper: The Industry Standard for Leak-Proof Cups

Key Features:

- Single- or double-sided polyethylene (PE) coating.

- Waterproof barrier to prevent liquid absorption.

- Lightweight yet strong structure for hot/cold beverages.

Applications:

- Hot/Cold Drink Cups: Standard for coffee, tea, smoothies, and sodas.

- Cost-Effective Solution: Widely used in fast-food chains, cafes, and food trucks.

Pros: Affordable, reliable, and compatible with standard manufacturing processes.

Cons: Limited recyclability due to plastic coating.

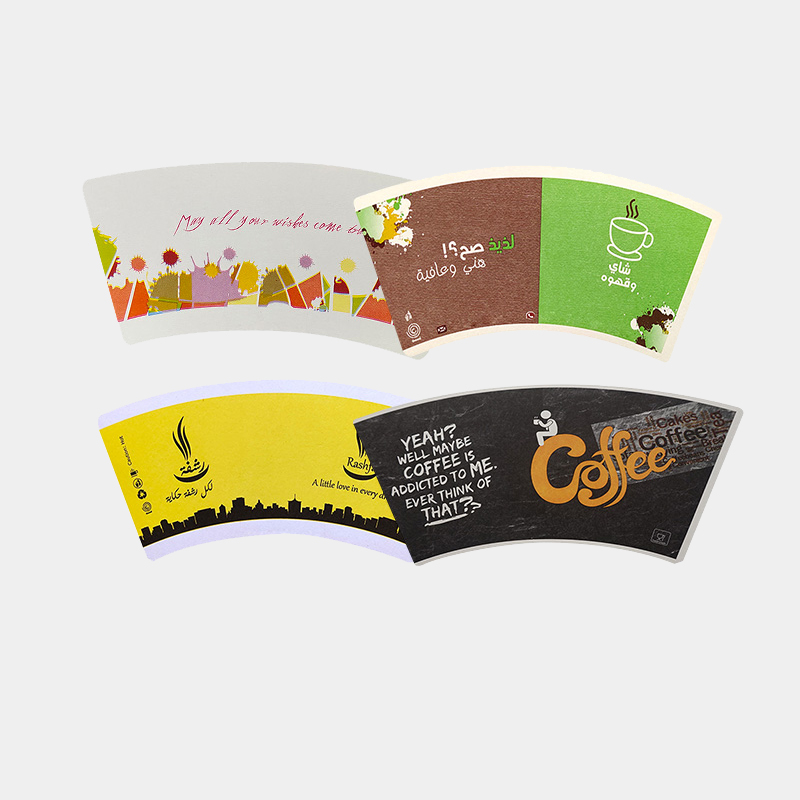

2. Single-Sided PE Coated Paper: Balancing Aesthetics and Function

Key Features:

- Coating applied to one side for liquid resistance.

- Uncoated side enables vibrant printing for branding.

Applications:

- Promotional Cups: Ideal for customized logos, designs, or seasonal themes.

- Restaurants and Events: Perfect for businesses emphasizing brand visibility.

Pros: High print quality, cost-effective for branded cups.

Cons: Less durable for extreme temperatures or long-term use.

3. Double-Sided PE Coated Paper: Enhanced Durability for High-Demand Use

Key Features:

- Full waterproof barrier on both sides.

- Superior insulation for temperature retention.

- Sturdy enough for outdoor events or transport.

Applications:

- Outdoor Events: Trade shows, festivals, or sports venues.

- Hot Beverage Transport: Coffee delivery services or bulk orders.

Pros: Leak-proof, excellent thermal resistance, long shelf life.

Cons: Higher cost compared to single-sided coatings.

4. Biodegradable Cupstock Paper: Leading the Green Revolution

Key Features:

- Made from sustainable materials: bamboo fiber, agricultural waste, or recycled pulp.

- Certified compostable (e.g., ASTM D6400 or TÜV OK Compost Industrial).

Applications:

- Eco-Conscious Brands: Cafés, zero-waste restaurants, or sustainability-focused events.

- Regulatory Compliance: Meeting mandates for reduced single-use plastics.

Pros: Reduces carbon footprint, aligns with global sustainability goals.

Cons: Slightly higher cost; requires proper composting facilities.

5. Waxed Cupstock Paper: A Classic for Extreme Temperatures

Key Features:

- Beeswax or paraffin coating for heat resistance (up to 200°F/93°C).

- Shiny finish adds a rustic or vintage aesthetic.

Applications:

- Hot Soups and Beverages: Ideal for events serving piping hot drinks or meals.

- Traditional Markets: Festivals, carnivals, or cultural events.

Pros: High heat tolerance, visually appealing.

Cons: Non-recyclable due to wax-paper bonding issues.

6. Aluminum Foil-Laminated Cupstock Paper: Luxury Meets Functionality

Key Features:

- Thin aluminum foil layer between paper layers.

- Reflective surface for insulation and metallic shine.

Applications:

- High-End Beverages: Premium bottled water, juice, or specialty coffee.

- Corporate Events: Luxury conferences, weddings, or exclusive tastings.

Pros: Superior insulation, elegant appearance, FDA-approved materials.

Cons: Higher production cost; heavier weight.

Choosing the Right Cupstock Paper for Your Business

- Cost vs. Sustainability: Opt for biodegradable or recycled options if targeting eco-conscious consumers.

- Temperature Needs: Double-sided PE or waxed paper for extreme heat; foil for insulation.

- Brand Aesthetics: Single-sided PE or foil for customizable, eye-catching designs.

- Regulations: Ensure compliance with local waste management laws (e.g., banning non-compostable materials).