Why Paper Cup Bottom Paper Matters: The Foundation of a Reliable Cup

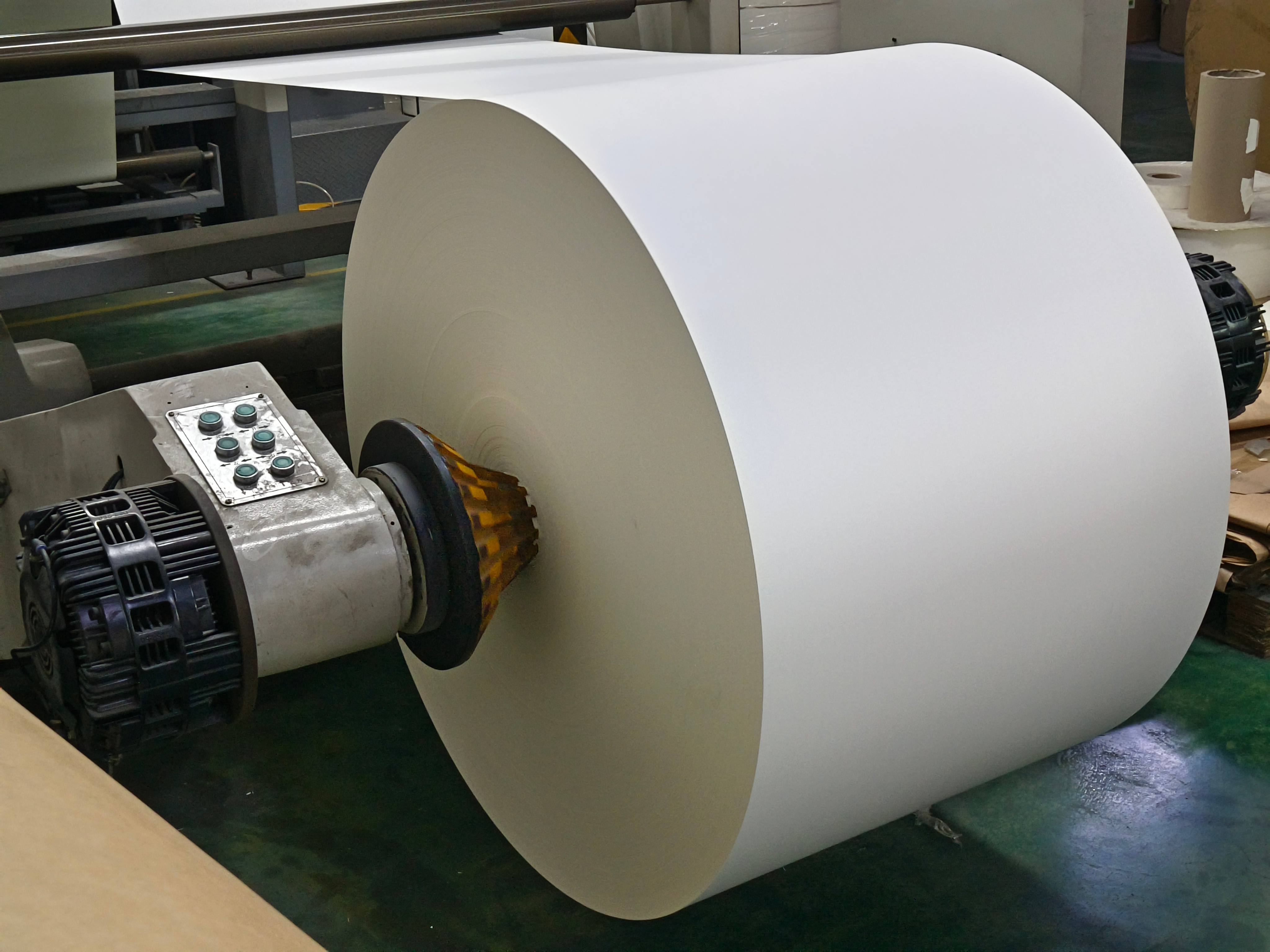

What is Bottom Paper?

Bottom paper is the circular base of a Paper Cup. It must bond tightly with the sidewall paper and withstand both pressure and heat sealing. Choosing the wrong bottom paper can lead to serious quality problems during or after cup formation.

Key Functions:

Ensures strong bonding with the sidewall paper during thermoforming

Supports the weight and liquid pressure from drinks

Provides a stable, standing base for the finished cup

Enhances the strength and leak-proof performance of the cup

Common Issues from Low-Quality Bottom Paper:

Leakage due to poor sealing or low-quality PE coating

Cup deformation or collapse caused by low grammage

Production inefficiency and waste if materials don’t match

Difficulty in forming due to uneven thickness or warping

Advice for Factory Buyers:

If your factory uses automatic paper cup machines, high consistency and precision in bottom paper is essential. We recommend:

Grammage range: 180–250gsm (depending on cup size)

PE coating (single or double) to ensure water and oil resistance

Use the same paper base as your cup body (kraft with kraft, white with white)

Ensure good flatness and roundness after die-cutting for smooth machine feeding

Avoid bottom paper that curls or warps during storage

Eco & Material Options:

We offer food-grade bottom paper in kraft or whiteboard base, with PE or water-based coatings to suit both conventional and eco-friendly cup production.

📦 What We Supply:

Grammage: 150–270gsm

Width:40mm-140mm

Base: Virgin Kraft Paper or Whiteboard

Coating: Single/Double PE, Water-based Coating

Die-cut or Roll Form Available

Custom sizes for all cup diameters

A high-quality paper cup starts from the bottom. Let us help you find the right base material to ensure stable production and strong final products.

Contact us today for samples or a free technical consultation.

Nanning Lvke Paper Co.,Ltd

Contact:Vicky Li

Email:victoria.li@nnlvke.com

Mobile/Whatsapp/:+8619977109815